Generating Point Clouds For Slicing Free-Form Objects For 3-D Printing

|

Generating Point Clouds For Slicing Free-Form Objects For 3-D Printing |

Abstract

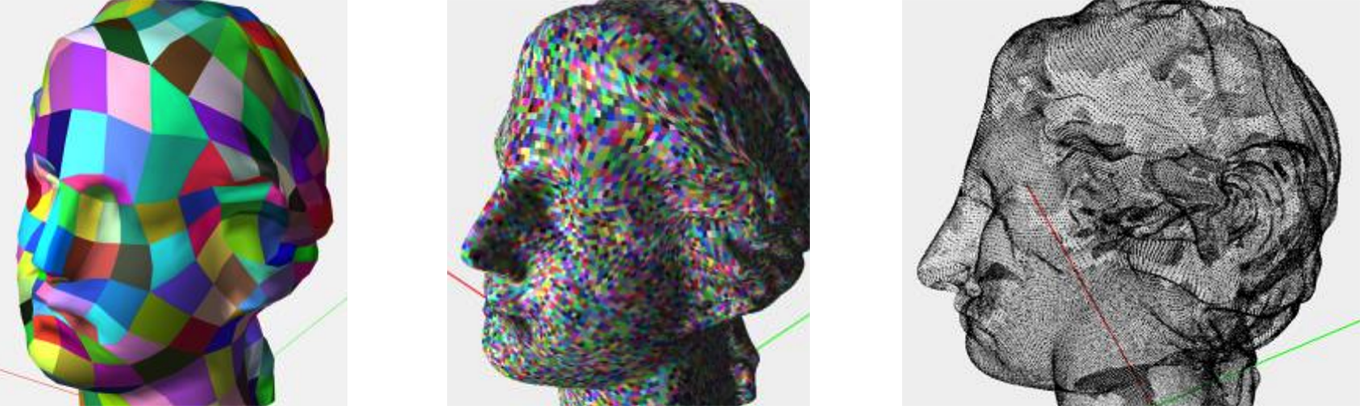

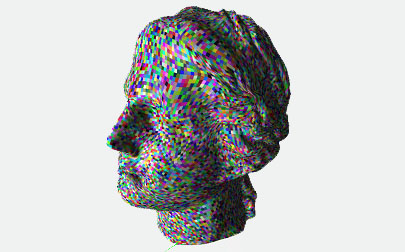

3-D printing, also known as additive manufacturing, has gained a lot of attention both within and outside CAD research. Even popular media have touted the technology as one of the game changer technologies of the 21st century. Simply stated, most printing devices add material to an unfinished part, layer by layer, until the entire object is completed. In order to make this happen, the object is sliced into thin layers which are produced and glued together. Since NURBS are the standard form of modeling tools, the process entails converting the NURBS into an STL model (piecewise triangular model) which is then sliced into a set of closed polygonal loops. In order to avoid the many problems with the STL-based slicing, in this paper we investigate a point cloud-based approach to direct slicing of NURBS based models. It uses the original NURBS model and converts the model into a point cloud, based on layer thickness and accuracy requirements, for direct slicing. The only major computational requirement is point evaluation which can be done error free and in an inexpensive manner. The generation of the point cloud is the main topic of this paper.

Downloads

Citation

William Oropallo, Les A Piegl, Paul Rosen, and Khairan Rajab. Generating Point Clouds For Slicing Free-Form Objects For 3-D Printing. Computer-Aided Design and Applications, 2017.

Bibtex

@article{oropallo2017generating,

title = {Generating Point Clouds for Slicing Free-Form Objects for 3-D Printing},

author = {Oropallo, William and Piegl, Les A and Rosen, Paul and Rajab, Khairan},

journal = {Computer-Aided Design and Applications},

volume = {14},

pages = {242--249},

year = {2017},

note = {textit{Presented at the CAD Conference and Exhibition 2017.}},

abstract = {3-D printing, also known as additive manufacturing, has gained a lot of

attention both within and outside CAD research. Even popular media have touted the

technology as one of the game changer technologies of the 21st century. Simply stated,

most printing devices add material to an unfinished part, layer by layer, until the

entire object is completed. In order to make this happen, the object is sliced into thin

layers which are produced and glued together. Since NURBS are the standard form of

modeling tools, the process entails converting the NURBS into an STL model (piecewise

triangular model) which is then sliced into a set of closed polygonal loops. In order to

avoid the many problems with the STL-based slicing, in this paper we investigate a point

cloud-based approach to direct slicing of NURBS based models. It uses the original NURBS

model and converts the model into a point cloud, based on layer thickness and accuracy

requirements, for direct slicing. The only major computational requirement is point

evaluation which can be done error free and in an inexpensive manner. The generation of

the point cloud is the main topic of this paper.}

}